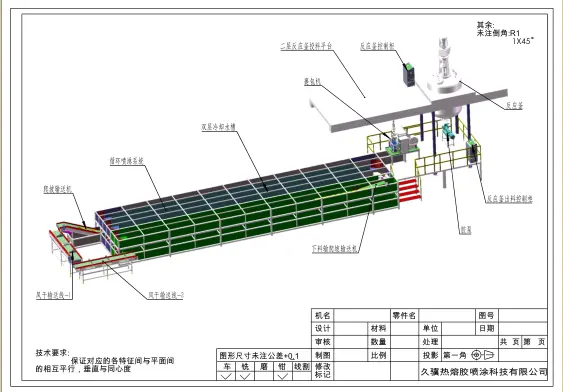

Hot Melt Pressure Sensitive Adhesive Production Line

Equipment series

Latest News

Video

- Hot melt pressure sensitive adhesive is a kind of hot melt adhesive with long time surface adhesion or long open time.

Hot melt pressure sensitive adhesive packaging than the general plastic rubber or no surface adhesion of the hot melt adhesive is much more difficult, there are factories will directly reactor mixing good pressure sensitive adhesive discharge directly into the metal hard disk coated with Teflon or silicone. After waiting for the hot melt pressure sensitive adhesive to cool down, it will be peeled off the metal disk, and then packaged with release paper or film, either directly or after cutting into small pieces. The common packaging weight is about 500g to 5000g per piece.

2. Barrel packaging When a large amount of adhesive is used or a faster melt speed is required, it can be considered that the molten hot melt pressure sensitive adhesive will flow directly into a silicone-coated 55-gallon paper drum with a top opening lid or a metal drum coated with epoxy resin. Packaging weight per pail is approximately 150 to 200 kilograms. The use of pail packaging must be accompanied by a pail melting system. The melting system consists of a disk with finned heating elements, which are inserted directly into the drum, leaving the unglued space.

The disk heats up and melts the adhesive side while pressing down, and the melted hot-melt pressure-sensitive adhesive is pumped through a gear pump into the tubes and back section of the gluing equipment.

3. The way of using hot melt adhesive film wrapping: Jiji film wrapping machine or Jiji pressure sensitive adhesive wrapping machine.

Pillow or sausage wrapping is a thin plastic film with no adhesive on the surface of the hot melt pressure sensitive adhesive. Pillow or sausage-shaped packaging is marketed in two common packaging systems.

The Fargo wrapper is a direct wrapping of a molten hot melt pressure sensitive adhesive and a plastic wrapping material through a co-extrusion die at high temperatures. The wrapped product is then cooled in a waterway after the adhesive strip has been crimped into small segments by a cyclic die press.

After the strip has cooled down, the strip is blown dry by air, and then each small piece of pillow or sausage-shaped hot-melt pressure-sensitive adhesive on the strip is ripped off by two rotating wheels at unequal speeds to obtain a single pillow or sausage-shaped piece of adhesive. The Jiji packaging machine pours the molten hot melt pressure sensitive adhesive directly into a preformed PE/EVA co-mingled plastic strip, seals it, and then cools it directly into an ice water channel.

After cooling, it forms a single pillow or sausage-shaped adhesive strip with no sticky surface.

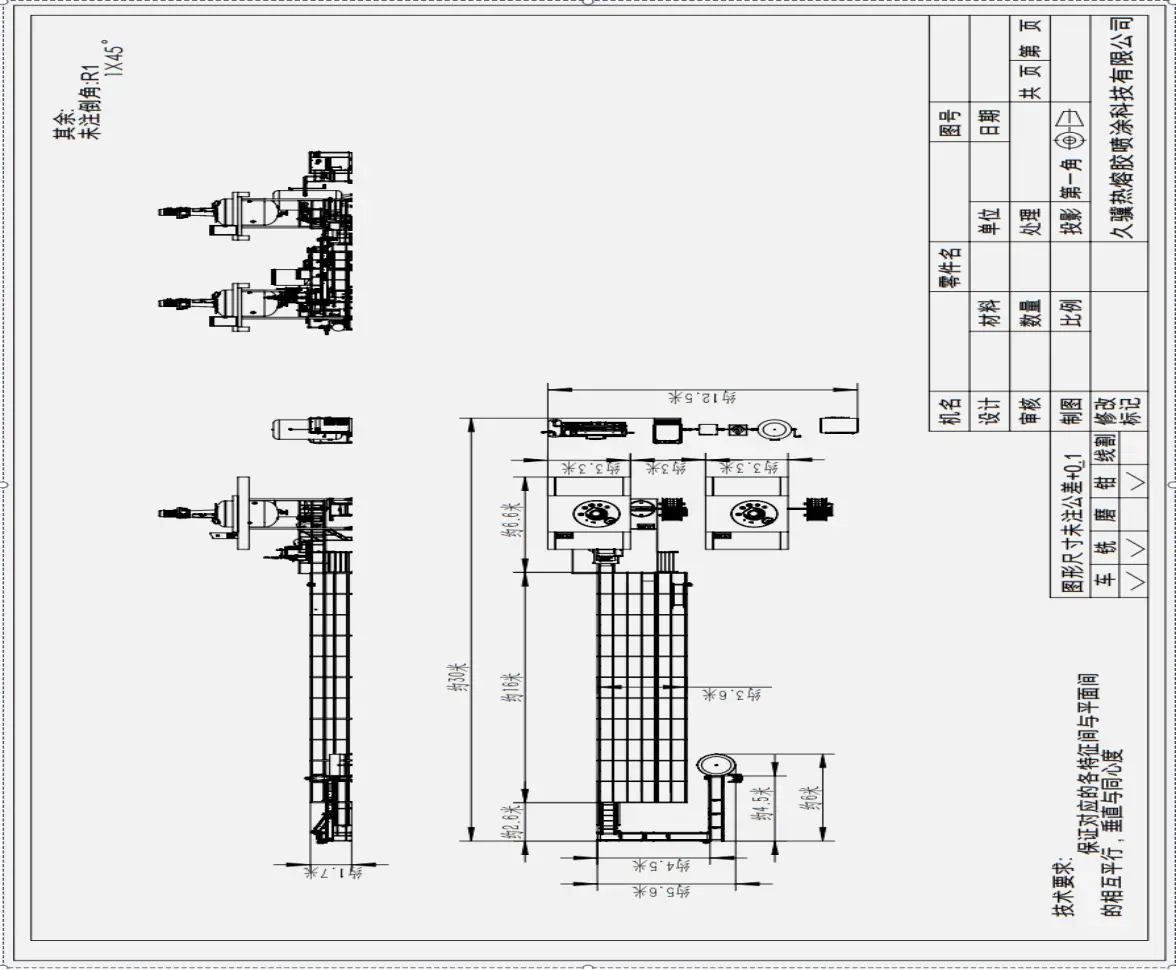

Layout

One. Mixing jug:

1, Capacity about: 3200L.

2, Wall thickness: inside 10mm outside 4mm.

3, Material: the tank is made of food-grade SUS304 stainless steel, the inner wall of 400-mesh mirror polishing.

4, tank inner size: Φ1500*1800mm outer size: 1800mm*2100mm.

5, low-speed motor power: BLD6-23-55KW-4 380V 50HZ, rotational speed: 56r/min.

6, with GRF-169-Y3055-4P-M4-FF157-IEC decelerator with carbon steel frame.

7, stirring paddle: double screw belt form stirring paddle, screw belt for reinforcement.

8, stirring shaft: diameter of about 140mm solid stainless steel stirring shaft bottom support bushing using PEEK high temperature resistance.

9, vacuum seal Vacuum degree: -0.1Mpa.

10,Double-layer heating with upper and lower material temperature probe, jacket with thermal insulation cotton.

11, coil heating Coil diameter: 89mm thickness: 4mm.

12, Coil do section design, two sections up and down, two in and two out.

13, The upper cover is directly welded to the kettle body, and the lower bottom is arc bottom.

14, Holes of top cover: manhole, reserved window, lighting, pressure gauge, air inlet and outlet holes, pressure relief valve, feeding hole, spare hole.

15, bottom outlet size: DN100 high temperature stainless steel pneumatic discharge outlet bottom offset from the center.

Second, electric heating pump:

1, Flow rate: 300ml/r (3m3/H, speed 160r).

2, Pressure: 0.6MPa.

3, head: 60M.

4, inlet and outlet caliber: DN65.

5, Motor: 380V/50HZ, 5.5KW, output speed: 160r.

6, Material: carbon steel.

7, with import and export flange 1 pair.

8, Heating method: heating tube electric heating.

9, Heating power: 1.45KW.

10, temperature control mode: temperature control table temperature control.

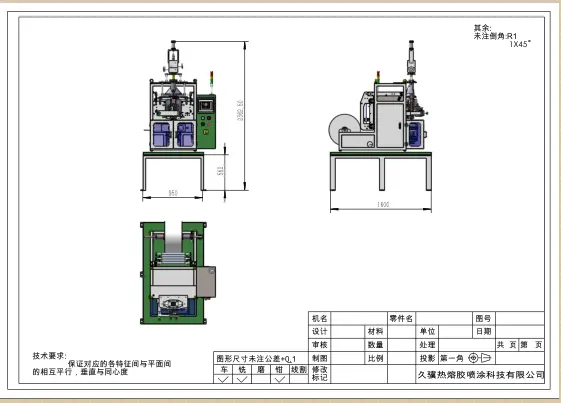

Third, the film packaging machine:

1, the main components, machine base material: SUS304;

2, motor: Delta servo motor

3, touch screen: 7 inch Xinjie touch screen.

4, the inner cavity heat exchange insulation.

5, Valve body material: SU304.

6, Pneumatic: Star cylinder.

7, temperature control: yudian temperature control meter

Four, cold water tank + climbing conveyor line + air drying conveyor line + receiving turntable:

1, water tank volume: 60 cubic meters

2, the upper climbing conveyor line: nylon chain conveyor belt

3, Lower climbing conveyor line: nylon chain plate conveyor belt

4, Air-drying conveying line: stainless steel mesh belt + fan

5、Hot air drying device: heated spiral air knife

6, 304 stainless steel receiving turntable

Five, vacuum pump:

1, pumping volume: 4.6 cubic meters / min.

2, Ultimate pressure: 3300MPa (-0.097MPa).

3, supporting power: 7.5KW.

4,Rotation speed: 1450rpm.

5, Matching: Vacuum Resistor 300L.

6, stainless steel water tank, base, stainless steel plate and frame heat exchanger, connecting pipeline, flange.

Six, ice water machine + water tower

1, water-cooled screw chiller 1 unit

2, Power: 60KW.

3, cooling water tower: 1 set.

4, cooling water pump: 1 set, 10KW.

5, chilled water pump: 1 set, 20KW.

Seven, screw air compressor

1, 1 permanent magnet frequency conversion screw air compressor.

2, processing air volume: 6.1 cubic meters / minute.

3, working pressure: 0.8MPa.

4, Voltage: 380V/50HZ.

5, Refrigerated drying chamber 1 set.

6, Processing gas volume: 6.5 cubic meters/minute.

7, Working pressure: 0.8MPa.

8, Voltage: 220V/50HZ.

9, Gas storage tank: 1 set

10,Volume:1000L

11, Working pressure: 0.8MPa.

12, Precision filter: 3 sets

13, Processing gas volume: 6.8 cubic meters / min.

14,Automatic drainer: 3 sets

15, Connecting pipe fittings: 1 set

Previous: 100KG Hot Melt Adhesive Machine